14 Tips for the Beginner Knifemaker

Knife making is a fun and rewarding hobby. Not only do you get to work with your hands and learn a new skill, but you also end up with a tool that can last a lifetime. It is a natural progression for knife users and enthusiasts to want to step into the realm of knife making. The reason for the leap is different for everybody. It can be to get better insight into what it takes to make a knife, it can be that your perfect knife doesn’t exist in the market, or it can be knife modders who want to do more than just modify premade blades. Whatever the reason may be, every new maker will start with more questions than they know what to do with. Hopefully this list of tips will give some direction and insight to the new maker. You may notice repetitive themes, phrases, or trends from tip to tip. This is because a lot of these ideas go hand-in-hand with one another and are important enough to be mentioned more than once.

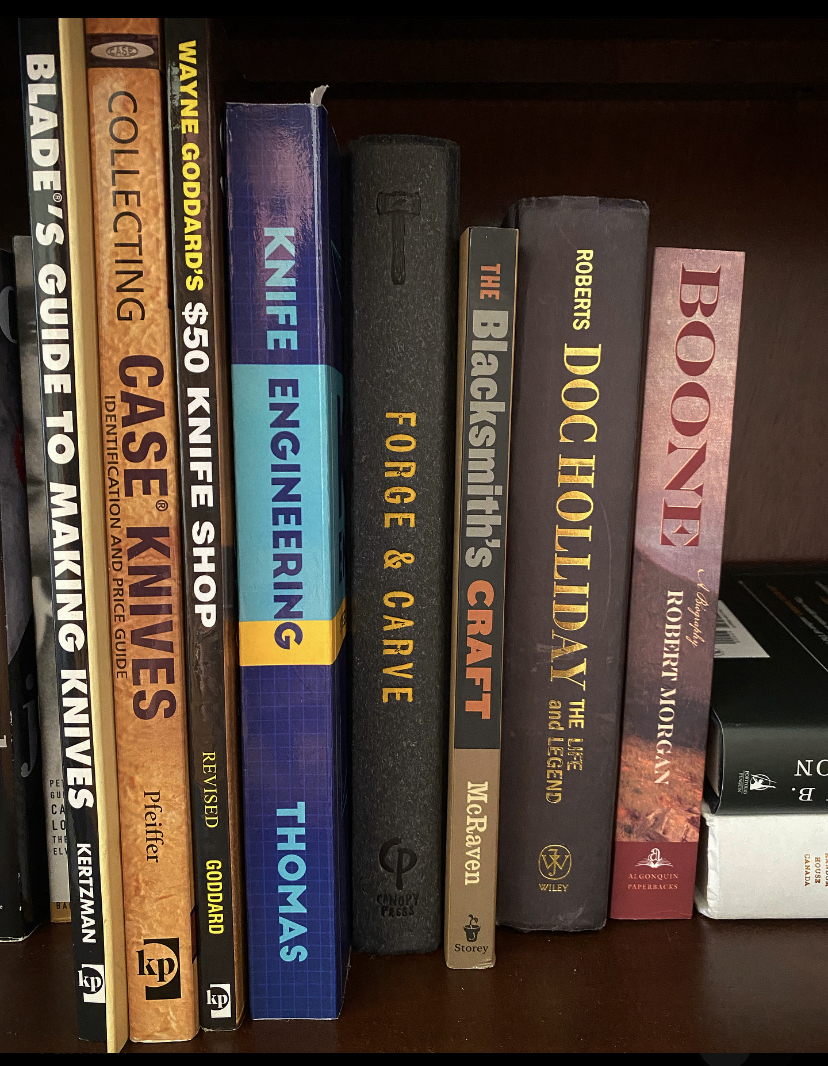

Do as much research as possible

When you start toying with the idea of making knives make sure you do your due diligence. Read as many books, blogs, and forum threads as you can. Watch as much knife making YouTube as you can stomach. A lot of the problems that you will run into have already been solved by guys who have been at it for years. Many of the questions that you have, or will have, have already been answered online. Reading and learning from other makers will save you time in the long run and will also teach you more about knife design and geometry.

Spend a lot time of looking at knives

Too often, the beginner knife maker will make the first knife design they come up with and more often than not, the knife ends up looking something like a prison shank. To avoid this, you need to know what does and does not work on a knife. You want to understand why a knife has a curve here and a straight edge there. It pays to spend a considerable amount of time looking at well-known knife designs from well-known makers. If you look at enough knives, you will start to understand what features do and do not work. Don’t try to reinvent the wheel, let those who have come before you pave your path.

Use proper PPE

I have heard too many horror stories about guys pulling metal shards out of their eyes to not mention PPE. Personal Protective Equipment (PPE) is the single most important thing to have in any workshop. You only have one set of eyes, ears, and lungs so it is essential that you protect them. Any time you turn on power tools you should have your eyes and ears protected and a respirator on. If I am in my workshop, I have my respirator on, 100% of the time, no exceptions. If I am using my grinder, band saw, or drill press I am wearing hearing protection as well as eye protection. I use my AirPods Pro as hearing protection; the noise cancelling feature is excellent in the shop. I recommend running down to Harbor Freight and buying several pairs of safety glasses and headphones. You will be surprised at how quickly these things grow legs and walk away. The old adage “two is one and one is none” really rings true here. I also recommend wearing boots and a canvas or leather apron, but these aren’t necessary.

Invest in the proper quality tools

As mentioned earlier, it is really fun to buy all of the “necessary” knife making equipment. I mean, who doesn’t want a shiny new 2×72 grinder and Evenheat kiln? As a beginner, this mindset is dangerous. It is easy to rack up a $5,000 tooling bill before putting steel to stone. Instead, focus on quality tools that won’t break the bank. Drill bits and files are a good place to start. For drilling annealed steel, cobalt drill bits do a pretty good job. Run down to the local Lowe’s or Home Depot and grab some Milwaukee or DeWalt cobalt bits. Be sure not to overheat your bits. For files, I would recommend starting with a Nicholson 14” half-round bastard file and an assortment of chainsaw files in various diameters. These files will help clean up all the rough edges on your freshly cut knife profile.

Don’t be afraid of your tools

Picking up an angle grinder and putting it to steel seems like a daunting task the first time you do it. The first time you feel that hot shower of sparks hit your forearms and feet is a little scary. Truthfully, it can be downright intimidating. It is easy to think of all the potential risks and dangers that power tools pose, but you can’t let that scare you off. In fact, having a healthy fear and respect of your tools can be beneficial. This respect will ensure that you always have your wits about you and that you don’t get too comfortable in front of your tooling. At the same time, you need to have confidence in your abilities and step up to your tools with the attitude “I know what I’m doing, and I am being safe about it.” A lot of power tool related injuries come from not having a firm grip on the grinder or from jumping the first time you feel a little kickback. Never forget that your tools can injure you if used improperly, so be sure to be safe with them.

Invest in good lighting

When jumping into any new hobby, the first thing everyone wants to do is buy a bunch of equipment that the “pros” use. Again, don’t fall into this trap. Granted, the tooling is cool and sexy, but a very important and unsexy investment is lighting. Lighting makes all the difference in knife making. It allows you to see any scratches and imperfections that are hiding in the shadows. I recommend buying one of those LED shop lights from Amazon or Menards. I wish that I had invested in better lighting way earlier in my knife making career.

Don’t use mild steel

Many people suggest running down to the hardware store and grabbing some mild steel to practice grinding knives on. In my opinion, this is not a good idea. Mild steel knives won’t harden, and you will end up with a chunk of knife shaped steel that cannot be sharpened. If you practice on something that will never result in a finished knife you may not do your best because “what’s the point.” It is a better idea to practice on a cheap knife steel that will result in a knife once you finish. It is hard to put your all into something that will only be a paperweight.

Use 1084

It is easy to look at the super steels that many knife makers are using and want to jump on the trend. Don’t let ambition and temptation lead you down the path of complex (and often, expensive) steels. Start with 1084 which is a quality high carbon steel that is cheap, easy to work with, and easy to heat treat using “at-home” methods. The heat treat process for 1084 is very forgiving which allows for a high-quality knife using more primitive heat treat methods.

Use inexpensive materials

Just like wanting to use cool, new, expensive steels, it is easy to look at modern handle materials and want to use them on your knife. Nowadays, it is easy to get caught up in figured woods, the newest carbon fiber patterns, patterned micartas, or even vintage micarta. While these materials are great and make beautiful handles, they are also expensive and not the easiest to work with. Start with materials that are workable and relatively inexpensive. Materials such as G-10 and canvas micarta are a great place to start. If you mess these up, they are replaceable, and you aren’t ruining a highly figured piece of wood.

Use sandpaper like it’s free

This is one of the most common tips you will see when you begin looking into making knives. It is a bitter pill to swallow but using sandpaper like it’s free is really a necessity. Steel, micarta, and G-10 are all very wear resistant materials and they will eat up sandpaper fast. The amount of time you will save on sanding by keeping fresh, sharp sandpaper on hand will shock you.

Take your time

When I first started making knives, I was overly excited about completing my first knife. As a result, I rushed the process so I could use it. The rushing led to mistakes and imperfections throughout the process. It took me awhile to let the initial excitement settle and follow the proper process. One of the most important things to do when starting to make knives is to take your time. The knife making process is slow, slower than you think it should be. Take your time at each step. When profiling your knife, make sure it looks like the pattern you settled on. When drilling your pin holes, make sure they are spaced correctly and that you don’t overheat your drill bit. When sanding the blade, or handles, make sure you get all the previous grit scratches out before moving on. There is nothing worse than moving on to the next step only to find out you missed something and must backtrack.

Don’t get frustrated

Everybody thinks that their knife is going to end up like something you see on the cover of a magazine. The reality is that your knife is going to come out looking like something between a pointy bar of steel and lumpy bar of steel. Throughout the process you will make mistakes and you will get frustrated. Don’t let these things deter you and put a bad taste in your mouth. Screw ups are part of the learning process. You can read everything under the sun and know exactly how to make the perfect knife. The only issue is that knowing and doing are two different things entirely. So, remember to enjoy the process, go slow, and embrace the mistakes. Use them as a learning opportunity.

Don’t expect perfection

This tip goes hand-in-hand with “don’t get frustrated.” It is easy to get caught up in exquisitely made customs and imagine yourself creating the same thing. However, this is almost never the case. Knife making is an art that takes a lifetime to learn and perfect. Truthfully, nobody has ever perfected the knife making process. There is always something to learn and improve upon. This applies to the maker with 40 years of experience and the beginner. This all being said, do not expect perfection. Do not expect your first several knives to come out how you picture them in your head. If you expect results that are above your skillset you will be disappointed in the knife you make and become discouraged. Remember each knife is a learning process, and any improvement is a success.

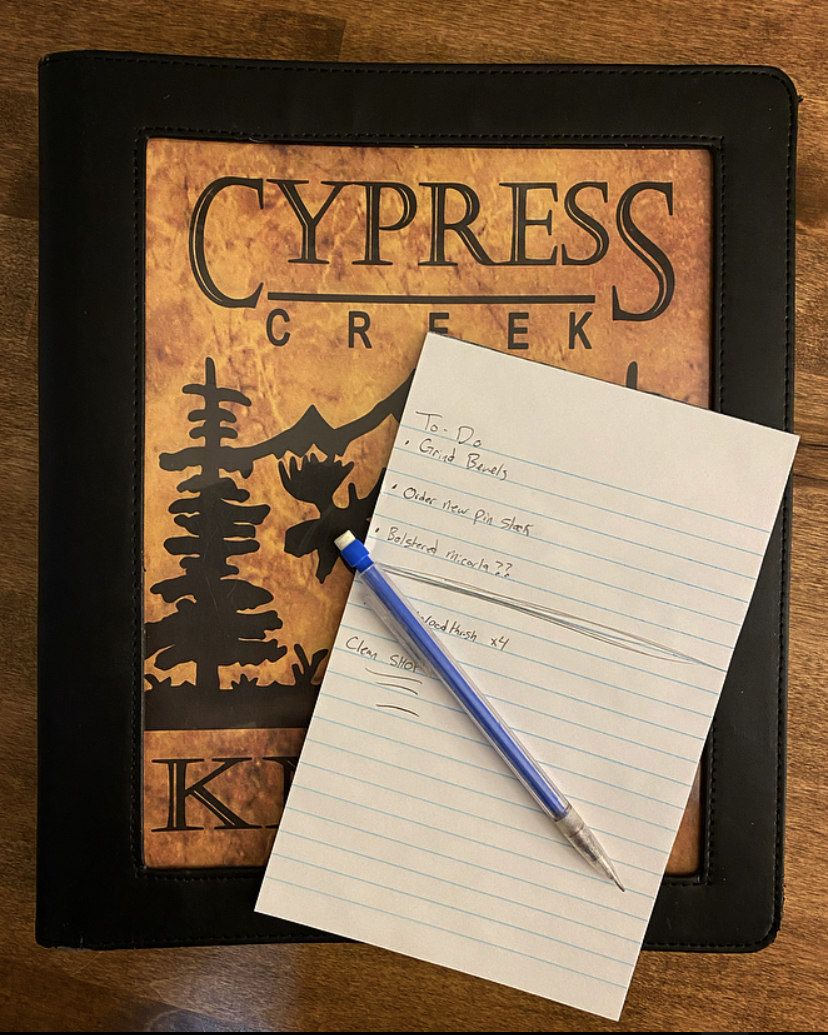

Keep a notebook handy

A notebook is the newest addition to my shop, and one of the most valuable tools I have. I could not tell you how many times I have told myself “I will remember that measurement, I will remember that part number, I will remember that cool handle scale combination,” and then promptly forgotten what I was supposed to remember. Having a notebook handy will mitigate any forgetful tendencies you may have. I keep track of all sorts of things in my notebook, and any thought that I think may be worth something gets written down in my notebook. I was surprised at how much writing things down helps with organization and efficiency in the shop. My notebook is truly one of the most valuable tools in my shop.